"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

12/17/2013 at 08:58 • Filed to: planelopnik

3

3

12

12

"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

12/17/2013 at 08:58 • Filed to: planelopnik |  3 3

|  12 12 |

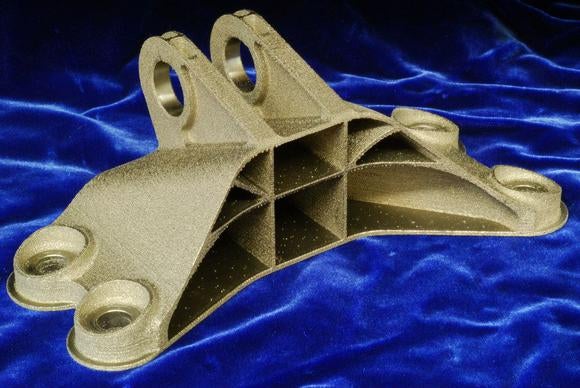

General Electric recently !!!error: Indecipherable SUB-paragraph formatting!!! for the online engineering community to help solve one of its biggest aviation challenges and knocked it out of the park. The aviation giant asked "makers," or do-it-yourselfers with engineering experience, to take a conventionally manufactured metal jet engine loading bracket and reimagine it for 3-D metal printing manufacturing to achieve a lighter weight, but still maintain its strength. The community response was outstanding — nearly 700 designs were submitted from 56 countries.

The winner, M. Arie Kurniawan, an engineer with zero aviation engineering experience living in Indonesia, won first place and took home a $7,000 prize. Kurniawan's design reduced the bracket's overall weight by nearly 84% while still maintaining the strength requirements necessary for real-world conditions, which at times needs to withstand loads as high as 9,500 pounds.

A conventional jet-engine bracket typically weighs around 100 pounds, and it usually takes six brackets to mount one engine to a plane's wing. Since the 3-D-printed equivalent has proved to be 84% lighter, that translates to a weight reduction of more than 1,000 pounds on a typical twin-engine jetliner. Bear in mind we're only talking about 12 redesigned brackets inside a plane that has thousands upon thousands of brackets and fasteners. As 3-D printing continues advancing beyond engine brackets, the potential net weight savings and corresponding fuel savings could be absolutely game-changing for airline operators.

Via !!!error: Indecipherable SUB-paragraph formatting!!!

For Sweden

> ttyymmnn

For Sweden

> ttyymmnn

12/17/2013 at 09:13 |

|

Thin internal baffles...

The eyes of maintenance inspectors everywhere just started twitching uncontrollably.

ttyymmnn

> For Sweden

ttyymmnn

> For Sweden

12/17/2013 at 09:16 |

|

My first thought about this article was about how these crowdsourced parts get tested. I'm sure the testing is rigorous, at least I hope so. I can only imagine the uproar if one of these parts fails tragically.

MonkeePuzzle

> For Sweden

MonkeePuzzle

> For Sweden

12/17/2013 at 09:19 |

|

yeas... so now we can cram 1000 lbs of... secret things in there MWHAHAHA

I'm assuming the finished piece would be sealed

Chteelers

> ttyymmnn

Chteelers

> ttyymmnn

12/17/2013 at 09:25 |

|

Surprised they didn't include that 4th wall. You could use standard CNC machining to achieve a very similar shape. A significant advantage to 3D printing is the ability to have internal pockets and features that are otherwise impossible through current cast/machining processes.

André - Volvo4Life

> ttyymmnn

André - Volvo4Life

> ttyymmnn

12/17/2013 at 09:29 |

|

$7k? That's a pretty shitty prize considering how much money GE saved using a "contest" to get this design.

ttyymmnn

> André - Volvo4Life

ttyymmnn

> André - Volvo4Life

12/17/2013 at 09:30 |

|

And how much they stand to gain long term.

f86sabre

> For Sweden

f86sabre

> For Sweden

12/17/2013 at 09:30 |

|

True dat. I fully appreciate the idea of lighter parts using innovative technology, but there won't be much allowable damage for that thing and you will be looking at replacing them when one gets nicked instead of doing a blend and treat. I would also wager, for personal experience, that GE won't be passing any kind of cost saving on to the customer.

MooseKnuckles

> André - Volvo4Life

MooseKnuckles

> André - Volvo4Life

12/17/2013 at 09:44 |

|

What's the alternative, try and produce the part yourself and then try to sell it without being strong armed?

UserNotFound

> Chteelers

UserNotFound

> Chteelers

12/17/2013 at 09:50 |

|

I'm going to guess it's a cutaway view.

Lime - Light

> Chteelers

Lime - Light

> Chteelers

12/17/2013 at 10:13 |

|

The first image is a cutaway.

RacinBob

> ttyymmnn

RacinBob

> ttyymmnn

12/17/2013 at 20:34 |

|

Great story, but remember what happens if the 16 pound engine bracket that replaced the 100 pound bracket fails after 5 years of usage. Engines fall off of planes, planes fall out of the air, and people die.

So, who wants to sign off on this weight reduction idea? Seat brackets, sure. Engine brackets hmmmmm.

ttyymmnn

> RacinBob

ttyymmnn

> RacinBob

12/17/2013 at 21:03 |

|

Chicago, 1979. I'm old enough to remember that one. No, I agree. I sure hope they test this thing to death. I'm not sure I want an engine bracket designed by some guy in his living room.